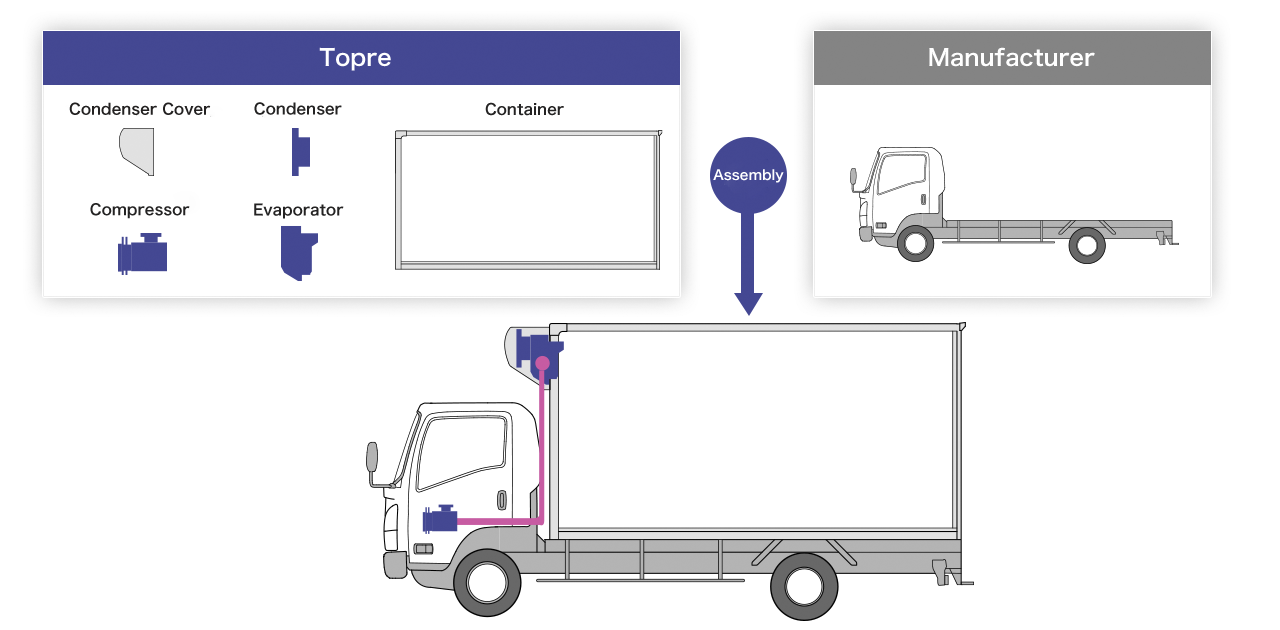

Constant Temperature Logistics Products

Topre’s integrated production system for precise thermal control.

Topre is involved in the integrated production of refrigeration equipment and containers for refrigerated trucks. We can manufacture refrigerated trucks capable of maintaining the optimal temperature range for the cargo, ranging from low-temperature to medium-temperature and heated specifications. We use Fiberglass Reinforced Panels (FRPs) to create containers that have both high thermal insulation and airtightness.

Unprecedented technologies and creativity, providing the next generation safe food.

Topre has created a range of advanced technologies, including the "XV series" that boasts the industry's lightest frame structure and high-efficiency heat exchange system for enhanced cooling performance. With our propriety technology and concepts, we have brought innovation to the food transportation environment. Our refrigerated truck lineup ranges from small, light-weight trucks, to 2-ton vehicles, up to large refrigerated trucks.

An array of advanced technologies supporting the advancement of refrigerated vehicles

Assortment of refrigerated vehicles to fulfill the varied demands of customers

Topre’s environmental efforts

With the business goal of manufacturing environmentally friendly refrigerated vehicle,

Topre has been taking care of the environment during the manufacturing process.

- Refrigerated vehicles are not subject to the act for automobile recycling. However, we are providing necessary information for appropriate disassembling and recycling of used refrigerated vehicles in accordance with our action plan.

- We prepared an internal guideline for the 3R’s (reduce, reuse, recycle) of waste materials of used refrigerated vehicles. We endeavor to manufacture environmentally friendly refrigerated vehicles by checking the guideline at the time of model and specification changes.

- We have set out the recycling target of waste materials arising from the manufacturing of refrigerated vehicles at 90% or more.

- We have been working to reduce four substances of concern in accordance with the reduction scheme established by Japan Auto-Body Industries Association, Inc.

- We do not use vinyl chloride materials for refrigerated vehicle components excluding some wiring harnesses.

- We have been working on structure development to reduce the use of wood materials.

- We have been working on utilization of non-CFC insulation material.

Disassembly manual for refrigerated/insulated body vehicles

Revision: February 15, 2011Download the manual