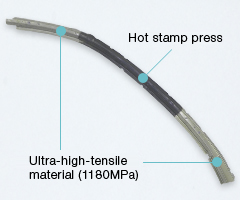

One of many advantages at Topre is metal press forming technology for high-tensile steel plates. High-tensile steel plate has especially high strength and lightness among many steel materials, but its press forming was very difficult. With our high technical capabilities, Topre was quick to start commercialization of press formed high-tensile steel plates. We have even succeeded in press forming of ultra-high-tensile steel plates with the strength of 1180MPa, which are now utilized as a framework material. There is a heightened awareness about improvement of fuel efficiency, and the development of hybrid cars and electric vehicles are advancing. Topre will continue to support automobile safety and environmental consciousness by delivering our unique press forming technology for high-tensile and ultra-high-tensile materials.

Press-related Products

Technology of metal press forming, changing the future of automobile.

Since our establishment in 1935, Topre has been advancing metal press forming technology. Utilizing unique die design technology and originality and sophisticated planning & developing ability as an independent manufacturer, we have been developing a multitude of high quality automobile parts. In recent years, we are cultivating lighter weight, reinforced automobile parts for the purpose of supporting achievement of CO2 emissions-reduction target while securing automobile safety. Topre will continue to deliver technologies for a better global environment and the future of automobile.

Ultra-high-tensile steel plates deliver the required strength and lightness.

Hot stamp press method improves the strength significantly.

Topre developed new hot stamp press method for more strength and lightness. By simultaneously implementing press and thermal processes on steel plates heated at 900℃, we improved the material strength significantly. In this method, mass-production of automobile parts with the strength of 1470MPa was accomplished. Topre is the first among Japanese automobile parts manufacturers to introduce the method at our US plant.

Topre will continue to develop and deliver new technologies for the future of automobile.

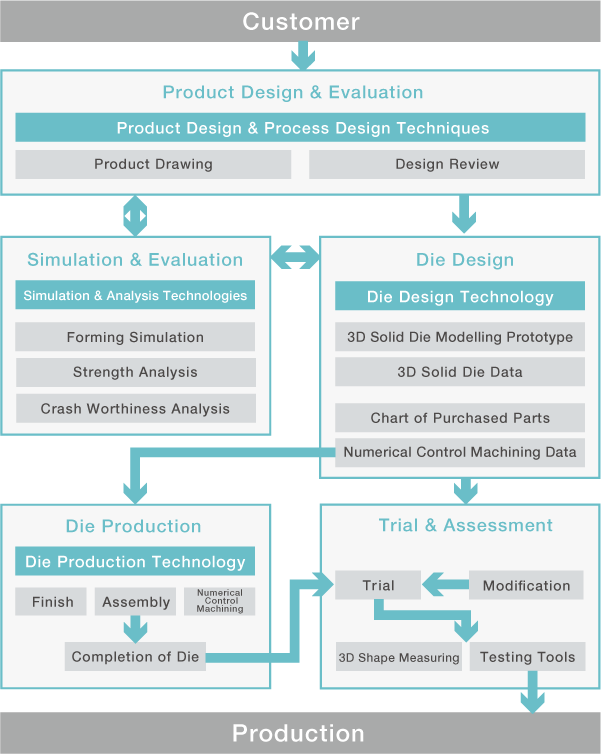

Design and evaluation cycle for speedy & accurate production.

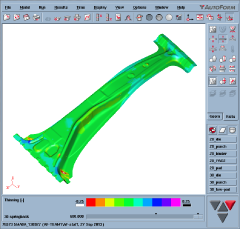

Topre is equipped with multiple types of CAD software and CAE system for high precision analysis so that we can respond to each customer’s requirements. This fully equipped development environment is completed by our integrated production system. We can carry out all processes, from development to mass-production, in a short turnaround to fulfill our customers’ demands quickly and accurately.

CAE※ system is utilized for forming simulation and highly accurate analysis of strength and crashworthiness.

※Computer Aided Engineering

Topre provides its signature technology

in daily lives and various business fields.

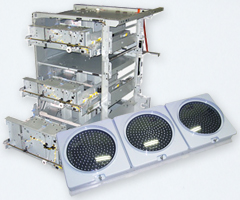

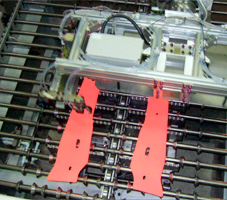

Our sophisticated metal press forming technology is utilized in other fields than the automobile industry. In the office automation equipment category, we have taken part in the early development stage of photocopiers and printers to ensure the high specifications demanded by manufacturers for their housings.

In the traffic light machine business, we have been developing easy to maintain and install products. Flexible application of our core technology in different business fields is one of our advantages.