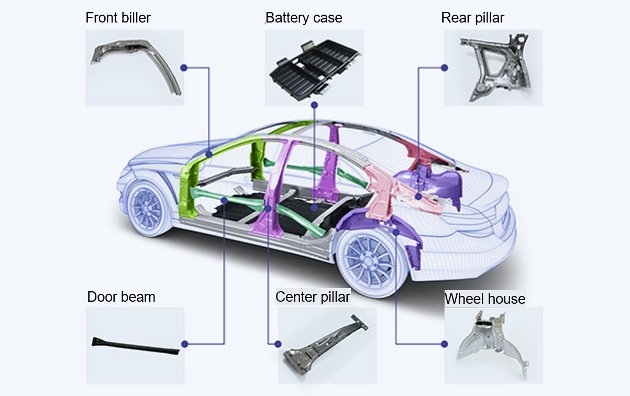

One of the group’s major strengths is its high-tensile steel plate processing technology.

The group makes products from high-tensile steel, which is particularly strong and extremely difficult to mold, with its advanced technological capabilities.

To support the reduction of CO₂ emissions while ensuring automobile safety, we will pursue further weight reductions and greater strength for each part and provide technologies for the global environment and a new automotive society.

- Expansion of application of cold-formed 1,470 MPa material to press parts

- Development and manufacture of battery cases for electric vehicles

We are advancing the development of technology for cold-formed 1,470 MPa press parts, which have the same strength as the hot stamp method with little CO₂ generated compared to the hot stamp method, which generates a large amount of CO₂.

With battery cases for electric vehicles, it is important to ensure characteristics such as water-tightness, battery storage capacity and strength, and we are developing technologies that lead to high quality and low cost by making full use of our production technology know-how and structural analysis.