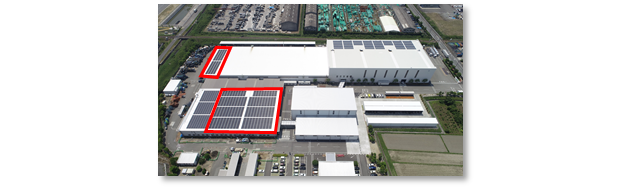

Topre Sagamihara Plant

・Installation on Press Plant 2 / one roof of Saitama Plan

・Expected reduction 172 t-CO₂ / year

Press Plant 2 Saitama Plant

The company established a Climate Change Measures Department in December 2021 to grasp the current state of CO₂ emissions throughout the group and to manage action plans aimed at the reduction of CO₂ emissions. Aiming for carbon neutrality by 2050, we built a climate change measures system consisting of top management, and are working on this.

Responses to climate change, a global-scale issue, is now a necessity. As an initiative towards the achievement of carbon neutrality, the company grasped CO₂ emissions in its production activities and set long-term targets for their reduction.

The group as a whole, both in Japan and overseas, will advance reductions step-by-step to achieve “a 30% reduction in CO₂ emissions in fiscal year 2030” and “carbon neutrality in fiscal year 2050,” based on improvements in energy saving, the installation of solar panels, purchasing of renewable electricity, and the trading of CO₂ emissions credits.

The group will fulfill its social responsibilities towards the realization of a sustainable society by implementing various measures.

In Japan, we began the installation of solar panels, the main part of our CO₂ reduction measures, in earnest from fiscal year 2022, and our CO₂ emission reductions have increased. Energy conservation measures are also advancing systematically in parallel, and the reduction results have increased.

Overseas too, like Japan, we are implementing surveys and making plans, and we plan to start energy conservation measures and the installation of solar panels from fiscal year 2023, gradually increasing the reduction results.

However, as production volumes are also increasing, we must accelerate further if emissions are grasped as the absolute volume.

To accelerate investment in CO₂ reductions, the company set internal carbon pricing (ICP) in Japan from fiscal year 2023. We will review ICP once a year in light of the situation in general and at the company. “Fiscal year 2023: 10,000 (yen / t-CO₂)”

In November 2022, we issued a news release announcing that we will make step-by-step investments in energy-saving facilities at bases in Japan to achieve the company’s fiscal year 2030 target for the reduction of CO₂ emissions. A reduction in CO₂ emissions of

10,000 tons is expected based on this initiative.

The company is strengthening the reduction of CO₂ emissions based on these initiatives.

Following on from each of Topre’s divisions and the nine divisions of the group’s domestic companies, each of the group’s overseas companies will start CO₂ reduction plans from fiscal year 2023.

[1] First, we will thoroughly implement everyday improvements for energy saving and the successive installation of solar panels on rooftops where they can be installed.

[2] Examples of items for consideration (other than solar panels)

<Lighting>

Switching to LED lights in plants and offices has largely been completed and we are advancing the change from mercury lamps, which consume a lot of electricity, to electricity-saving LED lights. At Tochigi Plant, for example, we reduced electricity consumption by about 70% by switching some lighting from mercury lamps to LED lights.

<Facilities>

We are upgrading to highly efficient power transformers and air conditioners. In addition, we are also working on everyday improvements such as reducing power consumption by adjusting the timing of the turning off of power to air compressors and the heating time of heat source equipment for each season.

<Logistics>

We are conducting activities aimed at the improvement of fuel efficiency by setting annual fuel efficiency targets. In addition, as an initiative to reduce CO₂ emissions associated with manufacturing, we are actively introducing battery- powered forklifts, which can be expected to reduce CO₂ emissions compared to conventional LPG- powered forklifts. Sagamihara Plant has introduced a total of 35 battery-powered forklifts since 2017.

<Use of renewable energy>

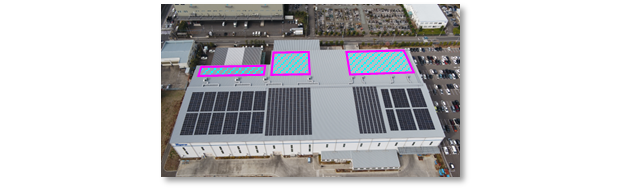

As an initiative for carbon neutrality, we plan to install solar panels in stages on all plant roofs where installation is possible. (We will consider the purchase of renewable energy power in the future.)

・Installation on Press Plant 2 / one roof of Saitama Plan

・Expected reduction 172 t-CO₂ / year

Press Plant 2 Saitama Plant

・Installation on the roof of Plant 3 warehouse

・Expected reduction 155 t-CO₂ / year

Plant 3 warehouse

・Installation on Plant 5 / roof of Warehouse 1

・Expected reduction 166 t-CO₂ / year

Plant 5 Warehouse 1

・Installation on logistics building / roof of plant building

・Expected reduction 255 t-CO₂ / year

< Front > Logistics building < Back > Plant building

・Plan for installation on Press Plant 2 / roof of Saitama Plant

・Expected reduction 361 t-CO₂ / year

Press Plant 2 Saitama Plant

・Plan for installation on Plant 7 / roof of welfare building

・Expected reduction:57 t-CO₂ / year

Plant 7 Welfare building

・Plan for installation in adjustment ponds A and B

・Expected reduction:321 t-CO₂ / year

Adjustment Pond A Adjustment Pond B

・Plan for installation on roof of Technology Center

・Expected reduction:197 t-CO₂ / year

Technology Center (Kurume Plant)

・Plan for installation on part of the roof of Toin Head Office Plant

・Expected reduction:175 t-CO₂ / year

・Plan for installation on part of the plant roof

・Expected reduction:1,537 t-CO₂ / year

・Plan for installation on part of the plant roof

・Expected reduction:1,889 t-CO₂ / year

・Plan for installation on part of the plant roof

・Expected reduction:761 t-CO₂ / year

| Bases | Results of initiatives in FY2022 | |

| Topre | Sagamihara Plant |

• Reduction of power consumption by switching to LED lighting in the plant and offices Reduction effect 23,365 kWh / year (replaced 244 fluorescent lamps) • Reduction of power consumption by upgrading air conditioners Reduction effect 1,000 kWh / year (upgraded 1 unit) • Reduction of power consumption by upgrading to battery-powered forklifts Reduction effect 22.2 t-CO₂ / year (upgraded 10 vehicles) • Installation of solar panels Press Plant 2 and Saitama Plant: Reduction effect 172 t-CO₂ / year |

| Hiroshima Plant |

Reduction of power consumption by upgrading to battery-powered forklifts Reduction effect 3.6 t-CO₂ / year (upgraded 1 vehicle) |

|

| Tochigi Plant |

• Installation of solar panels Plant 3 Warehouse: Reduction effect 155 t-CO₂ / year |

|

| Gifu Plant |

• Reduction of power consumption by upgrading transformers • Change of compressor control • Reduction of power consumption by upgrading to battery-powered forklifts Reduction effect 3.6 t-CO₂ / year (upgraded 1 vehicle) |

|

| Topre Kyushu |

• Installation of solar panels Plant 5 and Warehouse 1: Reduction effect 166 t-CO₂ / year • Reduction of power consumption by switching to LED lighting Reduction effect 170,000 kWh / year (replaced 138 mercury lamps) • Installation of solar panels Logistics building, plant building: Reduction effect 255 t-CO₂ / year |

|

| Topre Tokai |

Reduction of power consumption by switching from fluorescent lighting to LED lighting Toin Plant, Yokkaichi Plant, Suzuka Plant: Reduction effect 59.1 t-CO₂ / year | |

| Toprec | • Replaced gasoline-powered company vehicles with hybrid vehicles (18 vehicles) | |

| Topre (Foshan) |

• Reduction of power consumption by natural illumination of the plant and offices Reduction effect 4.3 t-CO₂ / year (equivalent to 20 fluorescent lights) • Reduction of power consumption by optimization of facilities Reduction effect 115.8 t-CO₂ / year (3 facilities in total, automatic control, increased efficiency and integration) • Reduction of power consumption by optimization of plant lines Reduction effect 156.8 t-CO₂ / year (review of material transport) |

|

| Topre (Xiangyang) |

Changes to air conditioner temperature settings Reduction effect 31.4 t-CO₂ / year |

|

| Topre (Wuhan) |

• Reduction of goods power by automating plant environment control Reduction effect 206,040 kWh / year |

|

| Topre Thailand | • Replaced gasoline-powered company vehicle with hybrid vehicle (1 vehicle) | |

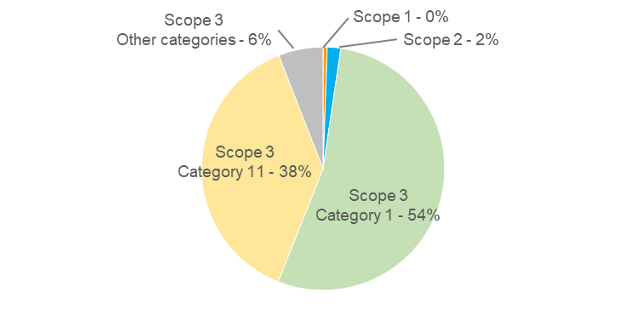

Scope 3 emissions are those by other companies aside from CO₂ emissions in production activities. The group’s biggest sources of Scope 3 emissions are in “Category 1 Purchased products and services (54%)” and “Category 11 Use of products sold (38%).”

The group recognizes that the reduction of Scope 3 emissions is an important issue, and set targets for efforts in categories where there are high emissions and the suppression of CO₂ can be expected

We will consider the selection and purchase of lowCO₂ materials and parts to reduce Category 1 emissions. With regard to Category 11 reductions, we will develop a lineup of refrigerated vehicles equipped with electric refrigeration equipment and promote replacement with low-GWP refrigerants. We are promoting subsidies for the purchase of electric vehicles with regard to the reduction of commuting by Category 7 employees.

| Subject category |

Subject sector | 2030 Target (Compared to FY2020) |

2050年 Target (Compared to FY2020) |

| 1 | Automotive Equipment Division |

30% reduction | 100% reduction |

| Product Division |

25% reduction | 75% reduction | |

| 11 | |||

| 7 | Domestic group companies |

last updated:2023/09/29 Update the content of the initiative