Environmental initiatives

Reduction of environmentally hazardous substances

Chemical substance management

Initiatives to reduce environmentally hazardous substances

We are working on the management and reduction of chemical substances that lead to environmental impacts in products designed by the company. We are promoting initiatives aimed mainly at the reduction of chemical substances subject to the PRTR Act and the management of chemical substances contained in products.

・Press-related products

Chemical substances for automotive parts are controlled using the automotive industry’s IMDS system*1.

We have stipulated chemical substance management rules based on ISO 14001 for our various purchased items, and are implementing chemical substance management. We have also stipulated a “List of Controlled Chemical Substances,” a management standard, and ask business partners to manage the chemical substances in the products they deliver with that and to deliver products managed under the same thinking as that of the company.

(Included in the “Topre Group Green Procurement Guidelines”)

・Temperature controlled logistics-related products

We are advancing initiatives to reduce the use of toluene, xylene, and methylbenzene, which are chemical substances with high emissions in manufacturing processes. In particular, we are transitioning from conventional paints to alternative paints aimed at reducing use of the chemical substances listed in the PRTR law.

・Air conditioning equipment-related products

The paints used in the blower product production process were subject to the PRTR Act, but after testing and evaluation, we obtained customer approval and switched to paints that did not fall under the PRTR Act. Due to this initiative, we were able to consider the health of workers and management became easier too as we were able to unify three kinds of paint into one.

・Electronic equipment-related products

We have introduced a dedicated management system for information on chemical substances contained in products and parts. Due to this initiative, we have become able to handle survey requests from customers and the work of providing answers smoothly, as well as searches specifying laws and regulations based on information on contained substances tabulated at the product, intermediate material and part levels.

By managing information on chemical substances contained in products positively, it becomes possible to obtain good evaluations from customers.

With purchased electronic products, we manage chemical substances using chemSHERPA*2

- List of Controlled Chemical Substances

|

※1 IMDS:

A supply chain environmental information transmission system developed by the Verband der Automobilindustrie (VDA) of Germany with the ELV Directive in mind

※2 chemSHERPA:

A data creation support tool led by the Ministry of Economy, Trade and Industry for the proper management of information on chemical substances contained in products throughout the supply chain, from upstream companies to downstream companies

|

Waste management

Waste generated from each place of business is thoroughly sorted to ensure appropriate treatment, environmental preservation and the improvement of public health. In this way, we are working to turn waste into resources and reduce its volume.

Waste management initiatives at the Topre Sagamihara Plant

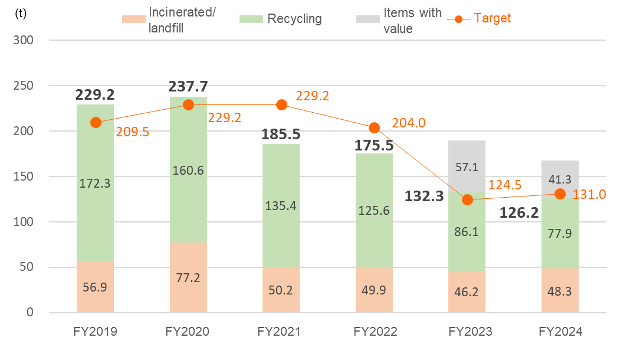

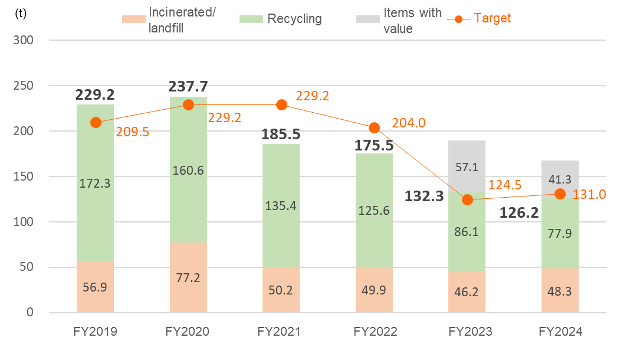

At our Sagamihara Plant, we conduct activities based on targets that we set for the reduction of waste to be generated every year, as part of our environmental management system. We are working on reducing waste by sorting refuse generated in business activities, excluding items with value such as scrap iron generated in pressing processes, into refuse to be incinerated and put into a landfill and recyclable refuse. Since fiscal year 2023, we have been working to further reduce recycling waste by further sorting items with value that contain recyclable resources as items with value.

We manage waste that includes hazardous substances in accordance with standards that are stricter than usual waste as “hazardous waste,” based on the Act on Waste Management and Public Cleaning. At the Sagamihara Plant, this includes waste PCBs, waste mercury, and other items generated when replacing transformers and lighting fixtures.

|

FY2021 |

FY2022 |

FY2023 |

FY2024 |

| Amount of hazardous waste generated(t) |

0.5 |

10.0 |

12.1 |

8.9 |

* Hazardous waste: Designated hazardous industrial waste

* Excludes the Saitama Plant

Waste generation targets and results

Waste generation targets and results

Effective use of resources

Waste generated from each place of business is sorted fully to ensure appropriate treatment, environmental preservation and the improvement of public health. We sort generated waste into different materials as far as possible to turn waste into resources and reduce its volume. In addition, to make effective use of resources, we improve yield rates during production and reuse detergents.

Japan

Topre Sagamihara Plant

The amount of waste emitted from Sagamihara Plant had been tending to increase from around 2020.

Therefore, the plant separated plastic to be disposed of thoroughly and started collecting waste plastic aimed at recycling from October 2021.

As a result, the plant was able to convert waste plastic into resources of value and achieved a reduction in waste of about 6 tons per year.

In addition, the plant started an initiative to recycle the collected waste plastic by commissioning a recycling company to recycle it into 45 l and 90 l garbage bags for

reuse as recycled garbage bags at the plant starting from February 2024.

We are planning in future to roll this out to other bases and group companies in addition to Sagamihara Plant.

Recycled garbage bags

Recycled garbage bags

Topre Tochigi Plant and Hiroshima Plant

At Tochigi Plant and Hiroshima Plant, compressing waste insulation material produced in the manufacture of refrigerated truck containers to less than 1/20th its original volume using a volume reduction machine enables the reduction of CO₂ emissions when transporting waste and use of the waste material as fuel.

Volume reducing machine Compressed waste material

Volume reducing machine Compressed waste material

Toho Transportation

Toho Transportation is promoting the adoption of work and office clothing made of recycled polyester fiber (60% or more recycled PET fiber) recycled from PET bottles and other materials.

Comfort, durability, etc., are virtually the same as conventional polyester materials, and with employees wearing Eco Mark-certified work and office uniforms, they are contributing to the reduction of our environmental impact.

Recycled Workwear

Recycled Workwear

Conservation of biodiversity

As raised in the group’s CSR activities, the Topre Group recognizes that the conservation of biodiversity is essential, and we will plan and implement biodiversity initiatives that are a premise of our business activities.

The following are activities picked up based on the results of implementation in fiscal year 2024.

Japan

Topre Sagamihara Plant

Sagamihara Plant is a member of the Sagamihara Environmental Improvement Association run by Sagamihara City and participates in surveys of aquatic life and water quality in the rivers of Sagamihara City, doing so twice in fiscal year 2024 on May 24 and October 11.

Topre Tokai

By raising donations for the Green Fund in Mie Prefecture, we are contributing to the creation of forests, greening, and the development of human resources to cooperate in the three areas of “forest development,” “the promotion of greening” and “international cooperation related to the promotion of forest development or greening” in Mie Prefecture.

Sagamihara Plant: Survey of aquatic life in a river

Sagamihara Plant: Survey of aquatic life in a river

Overseas

Topre Thailand

We have been carrying out mangrove planting activities for many years and have planted more than 2,000 trees.

In fiscal year 2024, we planted a total of 650 trees on November 27.

We will continue to contribute to the maintenance of diverse ecosystems in future too.

Number of mangrove trees planted

| Fiscal year |

2019 |

2020 |

2021 |

2022 |

2023 |

2024 |

| Number of trees planted |

325 |

350 |

330 |

500 |

500 |

650 |

Topre Thailand: Mangrove planting

Topre Thailand: Mangrove planting

Topre (Foshan)

We conducted tree-planting activities within the company on March 12, 2025, planting five trees.

Topre (Foshan): Tree-planting activities

Topre (Foshan): Tree-planting activities

Topre (Xiangyang)

Sixteen people participated in a tree-planting activity conducted by the Environmental Bureau of the Gaoxin District of Xiangyang City during the tree planting festival on May 15, 2024, planting 30 trees.

Topre (Xiangyang): Tree-planting activities

Topre (Xiangyang): Tree-planting activities

Topre Mexico

We participated in the greening and rehabilitation of Cerro Gordo Park in July 2024.

Topre Mexico: Participation in the greening and regeneration of a park

Topre Mexico: Participation in the greening and regeneration of a park

Topre India

On June 5, 2024, we held a commemorative ceremony and planted trees for World Environment Day.

Topre India: Tree planting at a commemorative ceremony for World Environment Day

Topre India: Tree planting at a commemorative ceremony for World Environment Day

Last updated:February 17, 2026 Update the content of the initiative